Operating as a privately held company founded in 2020, Allabout Seat combines agility with structured processes and certified quality systems to deliver reliable, repeatable engineering outcomes. With its focused expertise, rich benchmarking database, and comprehensive service portfolio, the company positions itself as a niche yet strategic partner for organizations seeking to accelerate automotive seating innovation while controlling risk, cost, and time‑to‑market.

For a leading premium Europen OEM project, Allabout Seat supported Tier 1 for 7 new vehicle program by delivering complete seat system architecture, detailed design, CAE‑driven weight optimization, prototypes, and industrialization support, helping achieve regulatory compliance in the first DV/PV loop and meeting aggressive weight‑reduction targets.

To combine deep seating engineering expertise with real‑world benchmarking insights, enabling our customers to launch better seats faster, with lower risk and higher value

To be the most trusted global partner for innovative, data‑driven automotive seating systems that enhance safety, comfort, and efficiency

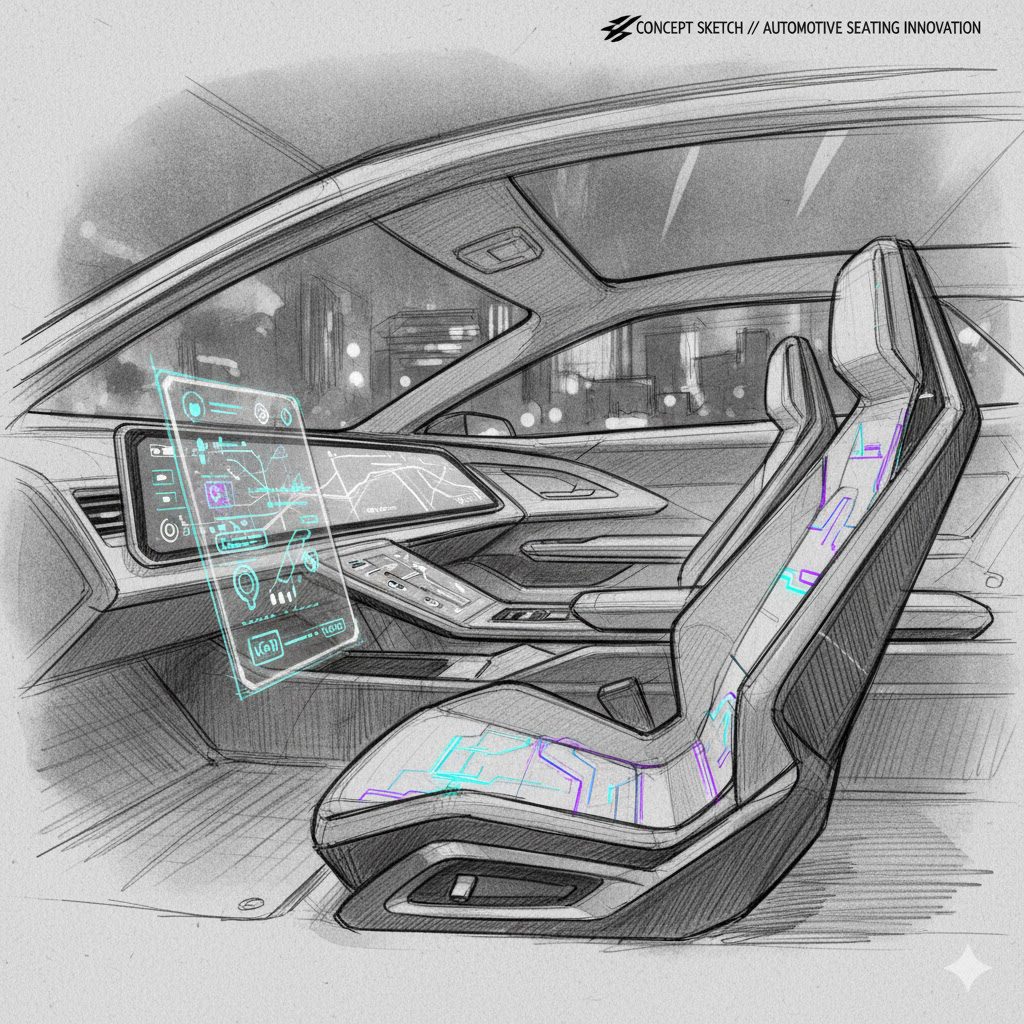

We bring together everything that drives innovation in automotive seating — research, design, validation, and production insight — all within one unified ecosystem.

Our integrated approach transforms complexity into clarity, enabling teams to move from concept to reality with speed and confidence.

What sets us apart is not just our capability, but our commitment to depth — the ability to connect data, design, and decisions seamlessly.

This holistic capability positions ASPL as a strategic partner for the next generation of seating systems developments.

Kohinoor World Tower T3, 12th Floor , 12-03, Opp Empire Estate, Old Mumbai – Pune Hwy, Pune, Maharashtra 411019

EMAIL : sales@autoseating.com

c/o TopTech Informatics K.K, Kyowa 15-bankan 8F, 2-5-8 Nishi Kanda, Chiyoda-ku, Tokyo 101-0065

EMAIL : sales@autoseating.com

Design that creates balance between customer requirements, performance and manufacturing quality.

Create optimal design for manufacturing process with right material selection.

Design that creates harmony with vehicle environment with fit and function through tolerance variation studies & effort requirements.

Identify early risks through various tools such as DFMEA, DRBFM, Engineering Risk assessment models.

Detailed CAE modelling methodology, material cards to build high correlated model with physical test.

Build Validation plan to evaluate the product & align test up with every detail to get get consistency, reliability and repeatability of performance.

Would you like to talk about Pilot Project ?